One of the workshops I run is to help team members understand root cause analysis. I use it with operations teams as well as product development teams. My workshop goal is to have people leave with a basic understanding and some practice.

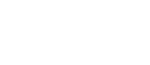

I created the diagram below to situate this workshop in a larger context of Kaizen (Continuous improvement).

One starting point is with a team using a Scrum board or Kanban to create BIG visible information. This supports teams in identifying problems or waste to stop the production line and investigate the problem using root cause analysis tools. I introduce two tools and have the participants practice with each:

- Ask Why five times – powerful technique for drilling down into problems.

- Fishbone (Ishikawa) Diagram – looks at the big picture around the problem.

Both of these improve quality to help teams go fast. 5S (sort, straighten, shine, standardize, sustain) is also totally applicable for software – it’s called clean code: coding standard, refactoring, etc.

Finally, the foundations for Kaizen and root cause analysis are:

- NO BLAME. Most problems are related to the system, not individuals.

- Team work and trust. If 100 people each help find 1% improvement, this will be sustainable.

- Genchi Genbustsu – Go and See. When you work on a problem, go to the source and get the facts for yourself. Root cause is about investigation and problem solving – see and think for yourself.

If you want to learn more, check out Implementing Lean Software Development: From Concept to Cash or Toyota Production System: Beyond Large-Scale Production.

Workshop Slides

Here is a slide deck I have used in training. It’s from last year, and would benefit from a refresh to cut down on the text – still very usable. As usual, you are welcome to use this as well as the diagram under Creative Commons license.